Arctic LNG-2: Commissioning the Arctic Scradeway Scader Pontoon

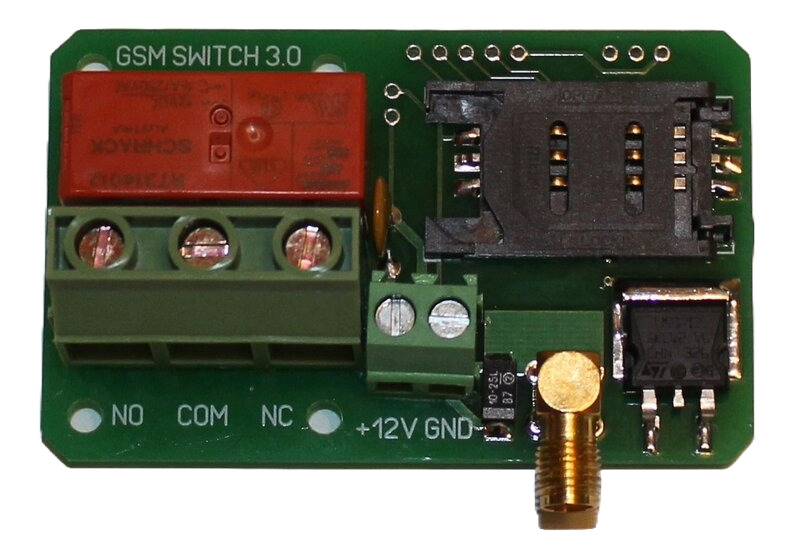

The Crisis: A Strategic Asset at a Standstill In the spring of 2023, the Arctic LNG-2 project faced a significant technical hurdle. The Arctic Scradeway Scader Pontoon, essential for subsea rock installation, was left unfinished at the pier. Following the exit of Boskalis from the project, the vessel’s complex automation remained in a non-operational state, threatening the timeline of the entire Arctic infrastructure development. The Solution: Reviving the Hardware Layer I joined a specialized team of mathematicians, programmers, and engineers to bring the vessel back to life. My responsibility was the foundational automation and hardware layer. Key engineering tasks included: Winch Control Systems: The pontoon features eight 35-ton constant tension electrically driven mooring winches. I was responsible for commissioning and fine-tuning their control systems for precise rock placement operations. Scrade Tower Integration: The 35m long Scrade tower, working in depths from 13 to 19.5m below the water level, required robust sensor integrity and reliable PLC communication. Hardware Recovery: Troubleshooting and re-configuring the programmable logic controllers and industrial communication protocols that were left without original manufacturer support. The Result: Arctic Operational Success Within a few months, our team transformed the stalled vessel into a reliable industrial tool. The Arctic Scradeway successfully carried out its mission, installing the stone foundations for floating LNG plants in the Arctic. This project proved that even when international support is withdrawn, deep engineering expertise at the hardware level can ensure the success of strategically important missions. “A system without documentation is just a pile of parts.” — In the Arctic, this isn’t just a slogan; it’s a survival rule. We didn’t just fix it; we made it maintainable and reliable. ...